ADDiTEC, a trailblazer in advanced metal manufacturing, is thrilled to announce a strategic partnership with MECHA, Inc., a distinguished full-service provider of machining services. This collaboration leverages ADDiTEC’s cutting-edge metal printing technologies with MECHA’s extensive capabilities in high volume precision machining and finishing services. About ADDiTEC: ADDiTEC has been at the forefront of innovation in advanced metal…

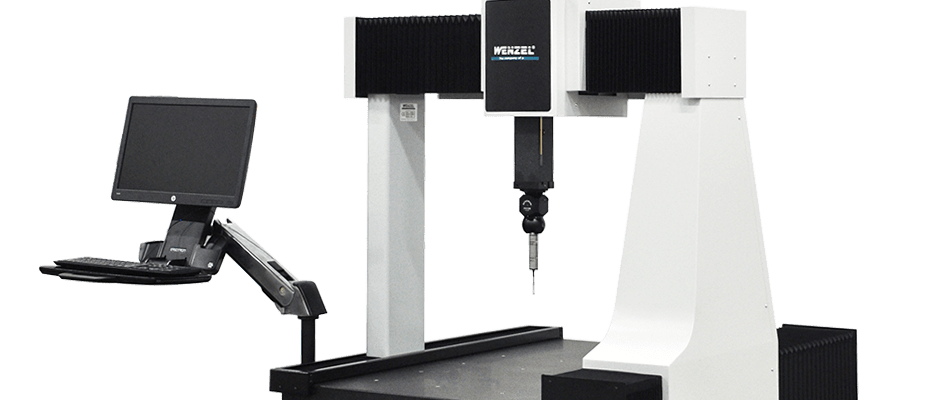

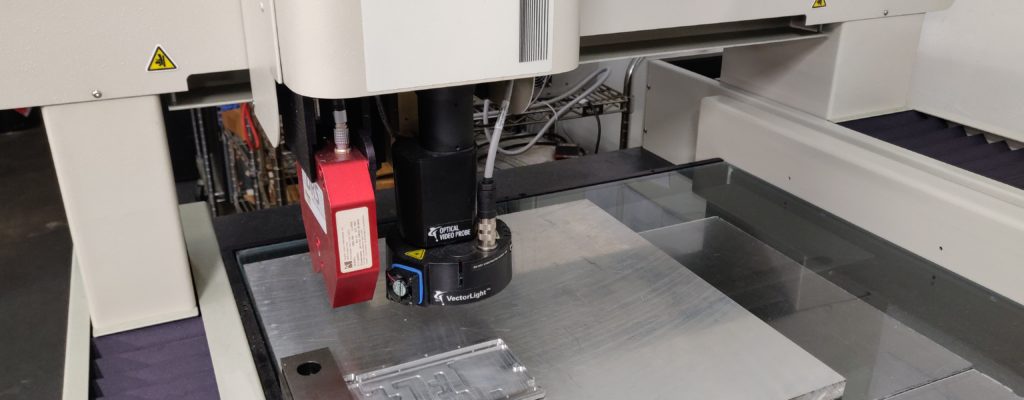

Read moreWenzel SF 55 CMM

Some of the parts we manufacture have extremely tight tolerances. Accordingly, we needed a coordinate measuring machine (CMM) to match the precision and accuracy of our machining capabilities. There are a lot of great CMM’s on the market, but we ultimately chose the Wenzel SF 55. Their pre-sales support was fantastic, answering all our questions…

Read moreWAZER Waterjet

We are developing a new product, and we needed a way to cut some material that is not easily machined. Because we are currently limited on space until our new facility is built, we researched compact waterjet machines. For our current needs, the WAZER waterjet machine seemed like a great choice. It may not have…

Read moreDMG Mori DMU 50

A little over a year ago, we needed a more accurate 5-axis machine to make some challenging parts for one of our customers. After much research, we decided to go with a DMG Mori DMU 50. We have been extremely pleased with the speed and precision of the machine thus far. This is not to…

Read moreDatron Neo+, 40,000 RPM!

Mecha has grown so much in recent years that we have run out of physical space in our building for new equipment. We needed to find a high performance, compact machine to help meet customer demand until we can find a new building. After much research, we decided that the Datron Neo+ was a perfect…

Read moreNew Laser Cutter – Trotec Speedy 360

In the past, Mecha outsourced any type of laser engraving requirement. We recently purchased a Trotec Speedy 360 to bring that process in-house. This has allowed us to shorten our lead-times reduce costs, and control quality better than ever with associated parts. We’re finding all kinds of other uses for the laser as well. It…

Read moreNew CMM – Keyence KM-T1200

Mecha added a new CMM recently. The Keyence KM-T1200 uses a touch probe system with software that makes it really easy to set up a new program. Once the program is completed, the operator simply follows the on-screen photos that show where to touch the part for a measurement. This addition to Mecha’s inspection arsenal…

Read moreSafety First!

Machining can be very dangerous. Sometimes parts can be ripped out of a vise during drilling or milling, causing significant damage. This is why CNC machines typically have safety glass on the front doors, and most newer machines by will not run with the doors open. At Mecha, we mill parts as aggressively as possible,…

Read moreDo Plating and Painting Thicknesses Matter?

The dimensions on almost all drawings for machined components are assumed to be after plating. However, plating thicknesses generally only matter when machining parts with tight tolerances (<0.001″). Most plating processes only add a couple tenths or less (<0.0002″) of thickness per side. This includes chromate conversion, Type II anodizing, and electroless nickel plating. Measuring…

Read moreAnodizing Thicknesses

This is a bit of an oversimplification, but when a part gets anodized, the anodize layer forms halfway into and halfway above the original surface. So if a drawing calls for 0.002″ of anodizing, then the part will “grow” in size by 0.001″ per side of the part. For example, if a raw part is…

Read more